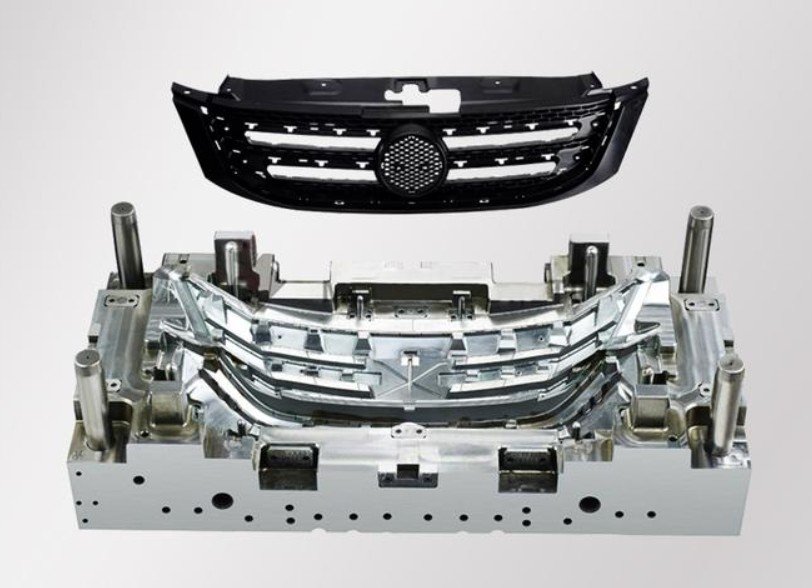

Prototype Injection Molding Services

At LXG Injection Molding, we provide complete plastic manufacturing solutions — from rapid prototyping to high-volume production. Our advanced technology, global expertise, and customer-first approach ensure every project is delivered with speed, accuracy, and reliability. Whether you need prototypes, tooling, or millions of molded parts, LXG is your trusted partner.

Why Choose Us for Prototype Moulding?

At LXG, we don’t just produce prototypes — we accelerate your design journey. Clients work with us because we:

Deliver 100% on-time without compromising precision

Bring 20+ years of prototyping & mold-making expertise

Offer competitive pricing with no MOQ constraints

Support thousands of injection moulding prototypes across industries

Ensure ISO-certified quality at every phase

Benefits of Prototype Injection Molding

Inconsistent prototype quality?

We enforce tight tolerances using FAI, CMM, and SPC oversight.

Unscalable prototyping?

From a single prototype injection mould to small batch production, we scale with you.

High prototyping costs?

Our refined tooling and smart material use reduce waste and cut expenses.

Bridge & Low-Volume Molding

Affordable, fast solutions for market testing.

Slow iteration cycles?

Turnaround in as little as 5–7 days for prototypes — enabling faster design loops.

Full-Scale Production

Millions of units with consistent, repeatable quality.

Types of Prototype Molding

Our prototype plastic molding services include:

Injection Moulding Prototypes — functional parts using production-grade plastics

Rapid Tooling & Prototype Moulds — fast, cost-effective moulds for early validation

Custom Prototype Injection Moulds — tailored tooling for your exact geometry

Pre-Production Prototypes — small runs with production intent

Rapid Prototype Molding Materials

Acrylonitrile Butadiene Styrene

Strong, impact-resistant plastic with excellent toughness and dimensional stability. Widely used for automotive parts, consumer goods, and electronics housings.

Polypropylene

Lightweight, chemical-resistant material with good fatigue strength. Ideal for packaging, automotive components, and medical devices due to its versatility and low cost.

Polycarbonate

High-strength, transparent plastic with excellent impact resistance and clarity. Commonly used in lenses, medical devices, and electronic housings.

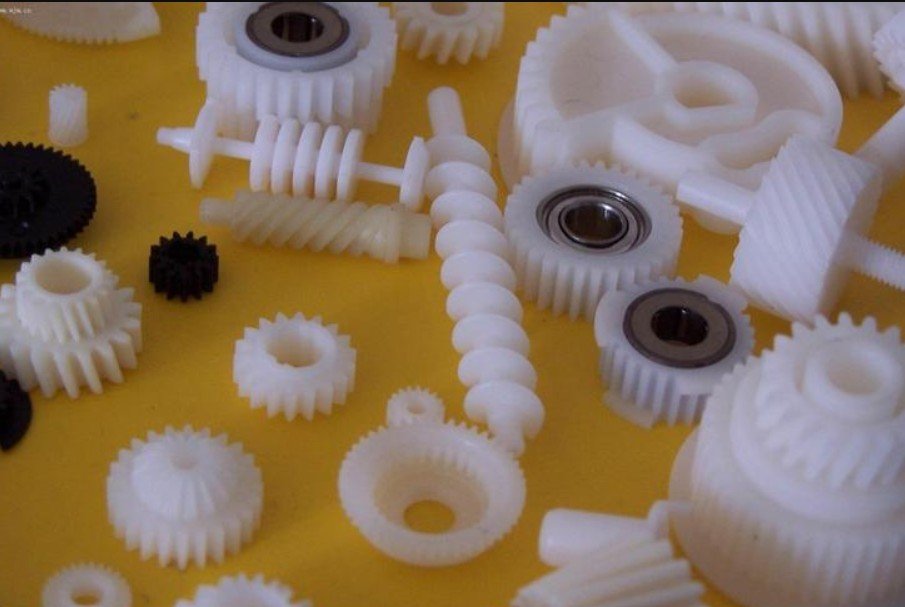

Nylon (PA6/PA66)

Strong, wear-resistant engineering plastic with high toughness and fatigue resistance. Perfect for gears, bearings, and automotive under-hood applications.

Polyethylene

Flexible, durable, and chemical-resistant material. Often used in containers, bottles, and packaging films.

Polystyrene

Lightweight, rigid, and cost-effective plastic with good clarity. Used for disposable items, packaging, and lightweight enclosures.

Polyoxymethylene

Low-friction, high-stiffness material excellent for precision components like gears, bearings, and automotive fuel systems.

Polymethyl Methacrylate

Clear, lightweight plastic with glass-like transparency and UV resistance. Widely used in lighting, displays, and windows.

Polybutylene Terephthalate

Strong engineering resin with excellent electrical insulation and chemical resistance. Common in connectors and automotive electrical parts.

Thermoplastic Elastomer

Rubber-like flexibility combined with easy processability. Used for grips, seals, and overmolded components.

Thermoplastic Polyurethane

Elastic, abrasion-resistant, and durable. Ideal for footwear, hoses, and protective cases.

Polyether Ether Ketone

High-performance polymer with extreme heat, chemical, and wear resistance. Used in aerospace, medical implants, and demanding automotive parts.

Polyetherimide

Heat-resistant engineering plastic with high strength and flame retardancy. Used in medical devices, aerospace, and automotive.

Polysulfone

Transparent, tough plastic with excellent heat resistance and dimensional stability. Common in plumbing and medical applications.

Liquid Crystal Polymer

High-flow, heat-resistant resin perfect for thin-wall precision parts in electronics and connectors.

High-Density Polyethylene

Tough, lightweight, and chemical-resistant. Used in bottles, containers, and piping.

Low-Density Polyethylene

Flexible, impact-resistant, and cost-effective. Common in plastic bags, films, and flexible containers.

Ethylene Vinyl Acetate

Soft, rubber-like material with excellent flexibility. Often used in footwear, sports gear, and packaging foams.

Polyvinyl Chloride

Durable, flame-retardant material with excellent chemical resistance. Common in pipes, fittings, and building materials.

Fluoropolymers

Exceptional chemical and heat resistance with low friction. Used in seals, gaskets, and high-performance tubing.

Ready to Build Smarter?

Partner with LXG Injection Molding for precision, speed, and reliability — from prototypes to full-scale production, we bring your ideas to life with confidence.

Our Prototype & Molding Capabilities

Rapid Prototyping & Bridge Molding

Prototype Injection Molding & Small Batch Runs

Multi-Material Moulding & Overmolding

Insert Moulding & In-Mold Assembly

Tooling Design & Prototype Mold Manufacturing

Post-Processing & Clean-Room Assembly

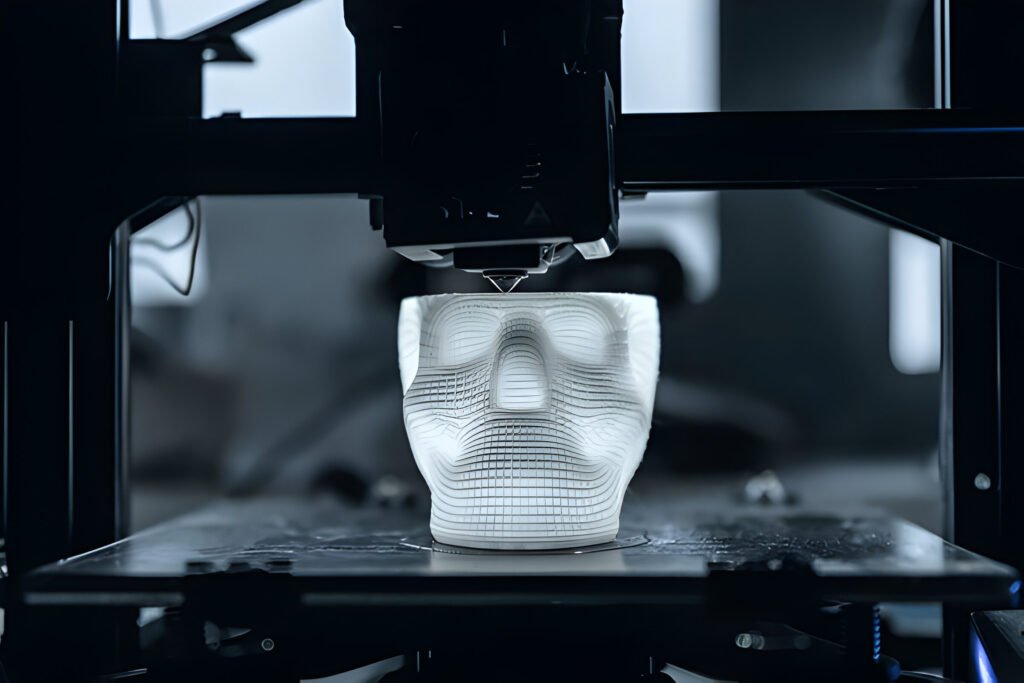

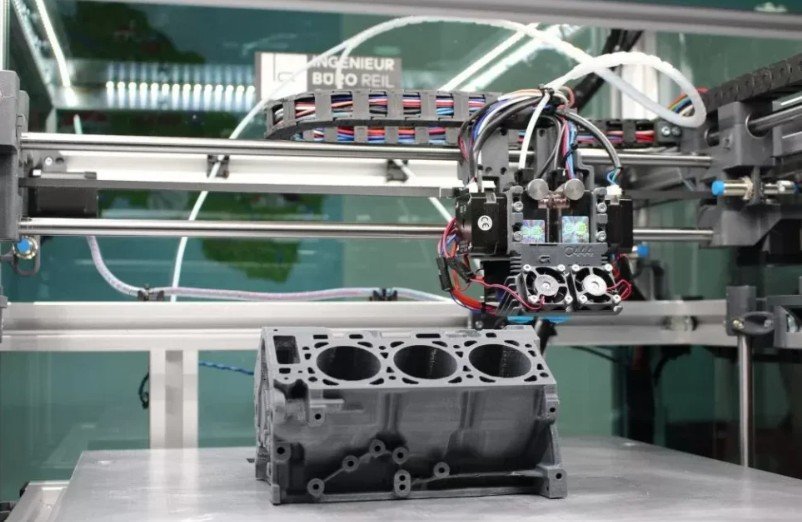

Tools and Technologies in Rapid Prototyping

| 3D Printing | Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | PolyJet Printing | Digital Light Processing (DLP) |

| CNC Machining | 3-Axis CNC | 5-Axis CNC | Multi-Axis CNC | High-Speed CNC | Precision CNC |

| Software | AutoCAD | SolidWorks | Fusion 360 | CATIA | Rhino |

| Materials | ABS Plastic | PLA Plastic | Resins | Metals | Composites |

| Finishing Techniques | Sanding | Polishing | Painting | Electroplating | Powder Coating |

| Quality Control | 3D Scanning | Coordinate Measuring Machines (CMM) | Optical Comparators | Surface Roughness Testers | Hardness Testers |

| Prototyping Services | Concept Models | Functional Prototypes | Visual Prototypes | Engineering Prototypes | Pre-Production Prototypes |

| Industry Applications | Automotive | Aerospace | Medical Devices | Consumer Electronics | Industrial Equipment |

Compare Our Prototype Parts

High-Precision Gear

- Material: Polycarbonate

- Tolerance: ±0.01mm

- Application: Electronics

- Feature: High Durability

VS

Custom Plastic Enclosure

- Material: PP

- Tolerance: ±0.02mm

- Application: Automotive

- Feature: Customizable Design

Overcoming Prototype Molding Challenges

Prototyping involves unique hurdles — tight deadlines, evolving designs, and material constraints. LXG confronts these with rapid tooling, strict in-line quality monitoring (FAI, CMM, SPC), and modular processes to adapt to change.

Our advanced prototyping machinery, simulation tools, and integrated workflows make us one of the most dependable prototype injection moulding providers in the world.

Our Testimonials

our client say's

Founded in 2000, Longxiang Group Limited (LXG Injection Molding) has grown into one of China’s most reputable mold makers, with 120 skilled employees and a 5,000 sq. meter workshop. Over the past 18+ years, the company has exported more than 3,000 molds to 38 countries worldwide. Its expertise spans automotive, electronics, IT, household products, and medical applications. With strict quality control, one-stop service, and rapid response support, LXG Injection Molding is a trusted global partner for precision plastic solutions.

Our Partners