Custom Injection Molding Manufacturer in USA

Is Your Injection Molding Partner Holding You Back?

Too many companies face obstacles such as

Inconsistent part quality

failed assemblies, higher scrap rates, and costly recalls

Slow lead times

delayed product launches and missed market windows

Regulatory non-compliance

increased audit risks and lost certifications

Design limitations

constraints on innovation and product functionality

Manufacturing inefficiencies

inflated costs and reduced profitability

Why Choose Us For Custom Injection Molding Manufacturer?

Partnering with LXG means choosing more than a supplier — it means gaining a strategic manufacturing partner committed to your success.

100% On-Time Delivery

At LXG Injection Molding, we never miss production deadlines. You get high-quality parts delivered on time, every time — without hidden costs or compromises in quality.

18+ Years of Experience

With over three decades of rapid injection molding expertise and tens of thousands of successful projects, LXG Injection Molding is the proven partner you can rely on.

Best Pricing Options

We break down cost barriers by offering free molds for high-volume projects and low-cost prototype molds, helping you reduce capital expenses and speed up development.

Trusted by Thousands

Thousands of satisfied customers continue to choose LXG Injection Molding for our reliable service, superior part quality, and fair pricing.

Flexible Solutions

Whether you need a single prototype or millions of production units, LXG Injection Molding adapts seamlessly to your requirements with the same focus on precision and efficiency.

Commitment to Quality

Every project we deliver at LXG Injection Molding reflects our dedication to durability, accuracy, and long-term reliability, ensuring your success in competitive markets.

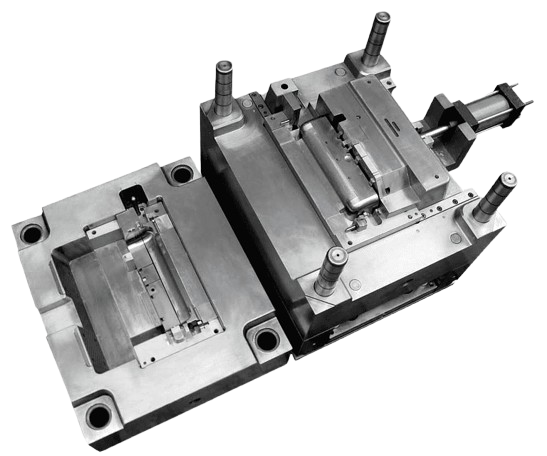

Injection MOLD Manufacturing on demand

100% Satisifeds Manufacturers

Get Instant Price, Projects lead time and DFM Feedback

Our mold injection manufacturer services

Injection Moulding

With advanced machinery and decades of expertise, LXG Injection Molding delivers high-volume, defect-free plastic parts with repeatable quality. From prototypes to millions of production units, we support a wide range of materials and industries. Our ISO-certified processes ensure precision, reliability, and cost efficiency — shaping products that meet global standards of excellence.

Plastic Tooling

Our expert tooling division designs and builds precision molds that form the foundation of every successful project. From single- to multi-cavity molds, hot-runner systems, or modular tooling, LXG Injection Molding ensures durability, accuracy, and efficiency. Every tool undergoes strict testing, guaranteeing consistent performance, lower long-term costs, and engineering excellence at scale.

Rapid Prototyping

At LXG Injection Molding, our rapid prototyping service helps you turn ideas into tangible parts quickly and cost-effectively. Using aluminum or soft-steel tools, we provide functional prototypes for design validation, fit testing, and market sampling. This accelerates development cycles, reduces risks, and ensures smarter decisions before moving into full production.

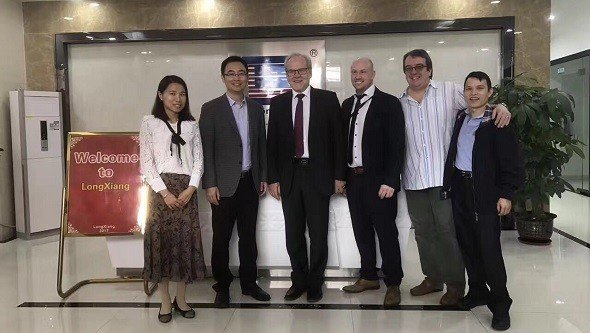

Global Reach, Local Support

LXG has delivered 3,000+ molds to over 38 countries worldwide. From automotive suppliers in Europe to medical innovators in the U.S., our global presence is matched with localized customer support, ensuring you get fast responses and reliable delivery wherever you are.

Quality Assurance at Every Step

At LXG, quality is built into the process — not inspected in afterward. Our systems include:

- First Article Inspection (FAI)

- CMM dimensional checks with GD&T

- Statistical Process Control (SPC)

- Lot traceability and certification

- Compliance with ISO, UL, RoHS, FDA standards

Our Proven Process — From Idea to Product

At LXG Injection Molding, we believe success comes from clarity, collaboration, and discipline at every stage of your project. Our process is designed to take you from an initial idea to fully validated, mass-produced parts with confidence.

Injection Molding TImeline

Step 1. Consultation & Quote

- Share your CAD files or product concepts.

- We sign NDAs for IP protection.

- You’ll receive a transparent quote with design feedback within 24–48 hours.

Step 2. Design Review & DFM

- Our engineers conduct a Design for Manufacturability (DFM) and Design for Assembly (DFA) analysis.

- Risky features like thin walls, sharp corners, or difficult undercuts are flagged.

- We suggest modifications to reduce costs, improve mold flow, and extend mold life.

Step 3. Prototype Molding

- Fast-turn prototype tooling made of aluminum or soft steel.

- Test parts in real-world conditions before investing in full production molds.

- Allows rapid iteration with lower cost.

Step 4. Mold Manufacturing

- Precision-built molds using CNC machining, EDM, and polishing.

- Options: single cavity, multi-cavity, hot runner, or family molds.

- Each mold undergoes tool trials and quality checks before production.

Step 5. Trial Runs & Validation

- First Article Inspection (FAI)

- Dimensional checks with CMM and GD&T standards

- Small pilot runs to validate performance under real conditions.

Step 6. Mass Production

- Scalable runs from hundreds to millions of units.

- Process parameters locked in for repeatable quality.

- Supported by SPC monitoring and automated quality checks

Step 7. Secondary Finishing

- Painting, pad printing, laser engraving, ultrasonic welding.

- Clean room assembly for medical-grade applications.

- Packaging tailored to client requirements.

Step 8. Packaging & Delivery

- Safe, customized packaging.

- Global shipping with tracking and export compliance.

- Long-term mold storage options for future runs.

Are You Ready?

Packages and web page editors now use Lorem Ipsum as their default model many web sites still in their.

Differentiators That Make LXG Better

Many companies offer injection molding — but not all are equal. Here’s how LXG Injection Molding compares to others:

| Feature / Benefit | Typical Competitors | LXG Injection Molding |

| Process Support | Limited engineering support | Full DFM/DFA reviews & proactive feedback |

| Material Range | Limited to common resins | 100+ materials including high-performance & medical grades |

| Scalability | Either prototype-only OR mass production | Seamless scale from 1 part to millions |

| Lead Times | 6–12 weeks typical | Prototypes in 5–7 days, production in 3–5 weeks |

| Order Size | Often high MOQs | No minimum order quantity |

| Quality Assurance | Standard inspections only | ISO-grade SPC, FAI, CMM, traceability |

| Services | Molding only | Tooling, molding, finishing, assembly under one roof |

| Global Reach | Limited regional service | Delivered 3,000+ molds to 38+ countries |

| Confidentiality | Basic NDAs | Strict IP protocols, secured data handling |

| Sustainability | Not always prioritized | Recyclable resins, eco-friendly processes, energy-efficient machines |

Precision in Every Mold, Excellence in Every Part

At LXG Injection Molding, precision is at the heart of everything we do. From initial design analysis to final production, every mold is engineered for accuracy, consistency, and long-term reliability. Our commitment ensures that your products meet the highest global standards.

awesome skills

Industries We Serve

At LXG Injection Molding, our expertise spans across diverse industries where precision, scalability, and reliability are critical. We tailor our processes to meet the unique needs of each sector, ensuring compliance with strict standards and enabling innovation at every stage.

Many companies offer injection molding — but not all are equal. Here’s how LXG Injection Molding compares to others:

Aerospace

High-quality plastic components engineered for demanding aerospace applications — from early prototyping and wind tunnel testing to hot-fire trials and final launch readiness. Our lightweight, durable parts help improve performance....

- Read More

Automotive

Supporting the evolution of mobility with rapid prototyping, bridge tooling, and full-scale production for traditional, electric, and autonomous vehicles. From dashboards and trim to connectors and housings, we deliver precision components with....

- Read More

Consumer Electronics

Delivering functional prototypes and on-demand production of casings, connectors, and housings for consumer and computer electronics. Our advanced overmolding and multi-material capabilities enhance both aesthetics and functionality.....

- Read More

Medical & Healthcare

Accelerating the development of life-saving medical devices and healthcare products. With ISO 13485 compliance, FDA-approved resins, and clean room assembly, we ensure biocompatibility, safety, and reliability for medical applications.....

- Read More

Industrial & Robotics

Durable, high-performance parts for robotics, automation systems, and industrial equipment. Our engineering resins and fiber-reinforced polymers withstand extreme loads, ensuring strength and long service life in demanding environments.....

- Read More

Sustainable Packaging

Partnering with innovators in eco-friendly packaging to create biodegradable containers, recyclable components, and lightweight designs. Our sustainable molding practices align with global initiatives to reduce waste and carbon.....

- Read More

Our Testimonials

our client say's

Founded in 2000, Longxiang Group Limited (LXG Injection Molding) has grown into one of China’s most reputable mold makers, with 120 skilled employees and a 5,000 sq. meter workshop. Over the past 18+ years, the company has exported more than 3,000 molds to 38 countries worldwide. Its expertise spans automotive, electronics, IT, household products, and medical applications. With strict quality control, one-stop service, and rapid response support, LXG Injection Molding is a trusted global partner for precision plastic solutions.

Advantages of Injection Molding

1. High Efficiency & Fast Production

- Once a mold is ready, cycle times can be as short as seconds per part.

- Enables mass production of thousands to millions of parts without bottlenecks.

- Example: An automotive supplier cut production time by 40% by moving from CNC machining to injection molding.

2. Cost-Effective at Scale

- Tooling requires initial investment, but per-unit costs drop dramatically at higher volumes.

- Multi-cavity molds produce multiple parts per cycle, multiplying output.

- Ideal for consumer products, electronics, and medical disposables.

3. Design Flexibility & Complexity

- Supports intricate designs: thin walls, internal threads, living hinges.

- Overmolding and insert molding integrate multiple materials/components into one part.

- Example: A medical device handle produced with rigid core + soft grip in one mold.

4. Wide Material Selection

- 100+ thermoplastics and elastomers available.

- Options include:

- Commodity plastics (ABS, PP, PE)

- Engineering resins (Nylon, PC, PBT)

- High-performance polymers (PEEK, PEI, PSU)

- Medical- and FDA-compliant grades

- Commodity plastics (ABS, PP, PE)

- Additives: glass fibers, UV stabilizers, flame retardants.

5. Excellent Consistency

- Automated systems ensure tight tolerances and repeatability.

- Perfect for regulated industries like automotive, aerospace, and healthcare.

6. Superior Surface Finishes

- Molds can be polished, textured, or patterned.

- Parts emerge with glossy, matte, or custom textures, often eliminating secondary finishing.

7. Strength & Durability

- Reinforced polymers can match or outperform metal in specific applications.

- Additives and fiber fillers improve tensile strength and impact resistance.

8. Eco-Friendly & Low Waste

- Hot-runner systems minimize scrap.

- Regrinding allows material recycling.

Options for bioplastics and recycled resins align with sustainability goals.

Frequently Asked Questions (FAQ)

Choosing the right injection molding partner often comes with many questions. At LXG Injection Molding, we want to give you clear, detailed answers so you feel confident every step of the way. Below you’ll find our 15 most frequently asked questions with in-depth responses.

Q1. How quickly can I receive my injection molded parts?

We understand speed is critical. For prototype molding, parts are often delivered in 3–7 days depending on design complexity and material availability. For production molding, delivery typically takes 3–5 weeks after mold approval. We also offer expedited services for urgent orders. By optimizing tooling and scheduling, we help clients cut weeks off their product development cycle.

Q2. What industries does LXG Injection Molding serve?

We provide solutions across a wide range of sectors:

- Automotive: dashboards, connectors, bumpers, trim parts.

- Medical Devices: housings, disposables, diagnostic parts, biocompatible components.

- Aerospace: lightweight yet strong housings, brackets, and structural pieces.

- Consumer Products: appliance parts, durable goods, toys, lifestyle products.

- Electronics: casings, connectors, protective housings.

Sustainable Packaging: biodegradable containers and eco-friendly packaging.

Our experience ensures compliance with industry-specific standards (ISO, FDA, UL).

Q3. Do you require a minimum order quantity (MOQ)?

No. Unlike many competitors, we have no minimum order requirement. Whether you need a single prototype, a pilot batch, or millions of units, we adapt to your requirements. Startups, small businesses, and multinational corporations all benefit from our flexible approach.

Q4. Who owns the mold after production?

Mold ownership is flexible. Typically, clients fully own their molds, which remain stored at our facilities for future runs. We also provide shared ownership or project-based licensing when budgets or project scopes require. Every mold is maintained, serviced, and stored under controlled conditions to maximize its lifespan and reliability.

Q5. Can LXG Injection Molding help me reduce production costs?

Yes — cost optimization is part of our DNA. Our engineering team reviews every design with Design for Manufacturability (DFM) principles, suggesting adjustments to:

- Reduce wall thickness where possible.

- Minimize unnecessary undercuts.

- Use family molds to produce related parts together.

Shorten cycle times with hot-runner systems.

Many clients save 10–25% in part cost after applying our recommendations.

Q6. What tolerances can you achieve?

We routinely hold tolerances of ±0.05 mm for most parts. For highly precise applications (medical, aerospace, micro-electronics), we can achieve tighter tolerances validated by:

- CMM (Coordinate Measuring Machine) inspections

- GD&T (Geometric Dimensioning & Tolerancing) checks

Statistical Process Control (SPC)

This ensures every part meets exact specifications, run after run.

Q7. How do you ensure part quality?

Quality is built into every stage of our process. We apply:

- First Article Inspection (FAI) before production approval.

- In-process CMM and GD&T measurements.

- Lot traceability for regulated industries.

- SPC monitoring to detect variations early.

Compliance with ISO 9001, ISO 13485, RoHS, FDA, and UL standards.

The result: consistent, defect-free, high-performance parts.

Q8. What materials can you mold?

We work with over 100 thermoplastics, elastomers, and specialty resins. This includes:

- Commodity plastics: ABS, PP, PE.

- Engineering plastics: Nylon, PC, PBT, PET.

- High-performance polymers: PEEK, PEI, PSU.

- Medical- and FDA-compliant materials.

Sustainable materials: biodegradable resins, recycled plastics.

We also provide advice on resin selection based on performance, cost, and environmental factors.

Q9. Do you offer secondary finishing and assembly?

Yes. Beyond molding, LXG offers:

- Surface finishing: trimming, polishing, painting, pad printing, hot stamping.

- Marking & branding: laser engraving, ultrasonic welding.

- Assembly services: from snap-fit assembly to bonding.

- Clean Room Assembly: Class 8 clean room packaging for medical products.

This saves clients the cost and effort of outsourcing secondary processes.

Q10. How do you protect client intellectual property (IP)?

Q11. Can you manage projects for international clients?

Absolutely. We have delivered over 3,000 molds to 38+ countries. Our global logistics team handles:

- Shipping arrangements with trusted freight partners.

- Export compliance and customs documentation.

Secure packaging to protect molds and parts during transit.

Clients benefit from worldwide reach with localized support.

Q12. What if I already have an existing mold with another supplier?

We specialize in tool transfers. When a client wants to switch suppliers, our team:

- Inspects and refurbishes the mold.

- Adjusts it to meet our production standards.

Runs validation trials before full-scale manufacturing.

This ensures smooth transitions without project delays.

Q13. What is overmolding and insert molding, and do you provide these?

Yes, we offer both advanced processes:

- Overmolding: combines two or more materials in a single part (e.g., soft-touch grips on hard handles).

- Insert molding: integrates components like screws, sensors, or metal reinforcements directly during molding.Both techniques reduce assembly needs, increase strength, and improve functionality.

Q14. What certifications does LXG Injection Molding have?

We comply with multiple international standards, including:

- ISO 9001 for quality managementq

- ISO 13485 for medical device production.

- FDA compliance for medical-grade resins.

UL and RoHS certifications for materials and processes.

This ensures clients receive parts that meet regulatory requirements.

Q15. Why should I choose LXG over other injection molding companies?

Here’s how we stand out:

- No MOQ barrier — we serve startups and global corporations alike.

- Faster lead times — prototypes in days, production in weeks.

- Full-service approach — from DFM to finishing, everything under one roof.

- Material expertise — commodity, engineering, medical, and eco-friendly plastics.

- Proven global track record — thousands of molds delivered worldwide.

- Customer-first philosophy — proactive communication, design feedback, and after-sales support.

Simply put, LXG Injection Molding isn’t just a supplier — we’re an engineering partner committed to your success.

Our Partners