Precision Injection Molding Solutions

At LXG Injection Molding, we provide complete plastic manufacturing solutions — from rapid prototyping to high-volume production. Our advanced technology, global expertise, and customer-first approach ensure every project is delivered with speed, accuracy, and reliability. Whether you need prototypes, tooling, or millions of molded parts, LXG is your trusted partner.

Why choose us?

At LXG, we do more than mold plastic — we mold confidence. Our customers trust us because we:

-

Deliver 100% on-time without compromising quality.

-

Offer 30+ years of expertise in mold-making and production.

-

Provide best pricing options with no MOQ requirements.

-

Support over 3,000 molds delivered worldwide.

-

Guarantee ISO-certified quality assurance at every stage.

Benefits of Producing Plastic Parts with LXG

Inconsistent part quality?

We ensure precision with FAI, CMM, and SPC monitoring.

Cost Efficiency

Concerned about high costs? Our optimized tooling and eco-friendly practices help reduce overall expenses.

Slow lead times

Prototypes in 5–7 days, production in 3–5 weeks.

Flexible Scaling

From a single prototype to millions of units, we lxgscale seamlessly to fit your production needs.

Regulatory non-compliance?

ISO 9001, ISO 13485, FDA, UL, and RoHS certified.

Trusted Global Partner

With 3,000+ molds delivered to 38 countries, LXG is a proven partner for manufacturers worldwide.

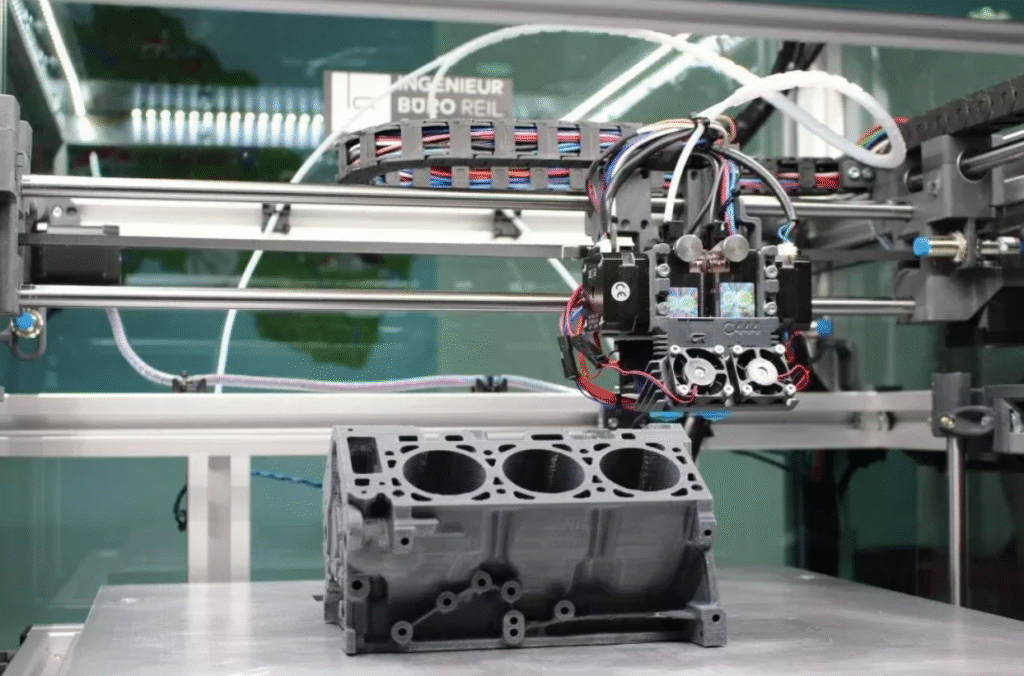

Types of Rapid Prototyping

Rapid prototyping uses different techniques to support various stages of product development. At LXG Injection Molding, we offer a full range of methods, each tailored to your needs:

-

Stereolithography (SLA): Produces highly detailed, accurate prototypes for visual and functional validation.

-

Selective Laser Sintering (SLS): Creates durable, functional parts ideal for testing under real-world conditions.

-

Fused Deposition Modeling (FDM): A cost-efficient method for simple, strong prototypes.

-

Digital Light Processing (DLP): Delivers high-resolution prototypes quickly and efficiently.

Each technique provides unique advantages, helping you select the best approach for your project’s requirements.

Injections Molding Materials

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Acrylonitrile Butadiene Styrene

Strong, impact-resistant plastic with excellent toughness and dimensional stability. Widely used for automotive parts, consumer goods, and electronics housings.

Polypropylene

Lightweight, chemical-resistant material with good fatigue strength. Ideal for packaging, automotive components, and medical devices due to its versatility and low cost.

Polycarbonate

High-strength, transparent plastic with excellent impact resistance and clarity. Commonly used in lenses, medical devices, and electronic housings.

Nylon (PA6/PA66)

Strong, wear-resistant engineering plastic with high toughness and fatigue resistance. Perfect for gears, bearings, and automotive under-hood applications.

Polyethylene

Flexible, durable, and chemical-resistant material. Often used in containers, bottles, and packaging films.

Polystyrene

Lightweight, rigid, and cost-effective plastic with good clarity. Used for disposable items, packaging, and lightweight enclosures.

Polyoxymethylene

Low-friction, high-stiffness material excellent for precision components like gears, bearings, and automotive fuel systems.

Polymethyl Methacrylate

Clear, lightweight plastic with glass-like transparency and UV resistance. Widely used in lighting, displays, and windows.

Polybutylene Terephthalate

Strong engineering resin with excellent electrical insulation and chemical resistance. Common in connectors and automotive electrical parts.

Thermoplastic Elastomer

Rubber-like flexibility combined with easy processability. Used for grips, seals, and overmolded components.

Thermoplastic Polyurethane

Elastic, abrasion-resistant, and durable. Ideal for footwear, hoses, and protective cases.

Polyether Ether Ketone

High-performance polymer with extreme heat, chemical, and wear resistance. Used in aerospace, medical implants, and demanding automotive parts.

Polyetherimide

Heat-resistant engineering plastic with high strength and flame retardancy. Used in medical devices, aerospace, and automotive.

Polysulfone

Transparent, tough plastic with excellent heat resistance and dimensional stability. Common in plumbing and medical applications.

Liquid Crystal Polymer

High-flow, heat-resistant resin perfect for thin-wall precision parts in electronics and connectors.

High-Density Polyethylene

Tough, lightweight, and chemical-resistant. Used in bottles, containers, and piping.

Low-Density Polyethylene

Flexible, impact-resistant, and cost-effective. Common in plastic bags, films, and flexible containers.

Ethylene Vinyl Acetate

Soft, rubber-like material with excellent flexibility. Often used in footwear, sports gear, and packaging foams.

Polyvinyl Chloride

Durable, flame-retardant material with excellent chemical resistance. Common in pipes, fittings, and building materials.

Fluoropolymers

Exceptional chemical and heat resistance with low friction. Used in seals, gaskets, and high-performance tubing.

Ready to Build Smarter?

Partner with LXG Injection Molding for precision, speed, and reliability — from prototypes to full-scale production, we bring your ideas to life with confidence.

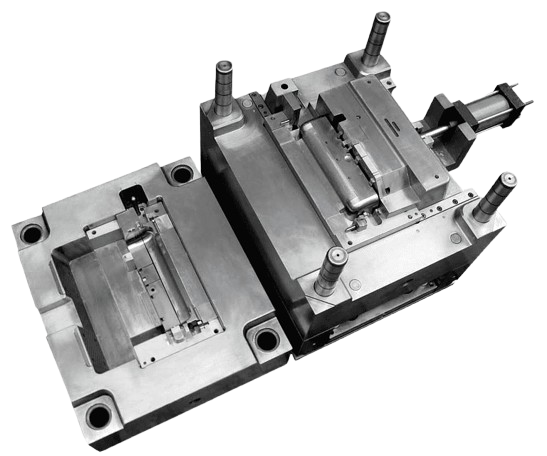

Our Expertise & Capabilities

Rapid Prototyping & Bridge Molding

Production Injection Molding

Multi-Material & Overmolding

Insert Molding & In-Mold Assembly

Tooling Design & Manufacturing

Post-Processing & Clean Room Assembly

Differentiators That Make LXG Better

Many companies offer injection molding — but not all are equal. Here’s how LXG Injection Molding compares to others:

| Feature / Benefit | Typical Competitors | LXG Injection Molding |

| Process Support | Limited engineering support | Full DFM/DFA reviews & proactive feedback |

| Material Range | Limited to common resins | 100+ materials including high-performance & medical grades |

| Scalability | Either prototype-only OR mass production | Seamless scale from 1 part to millions |

| Lead Times | 6–12 weeks typical | Prototypes in 5–7 days, production in 3–5 weeks |

| Order Size | Often high MOQs | No minimum order quantity |

| Quality Assurance | Standard inspections only | ISO-grade SPC, FAI, CMM, traceability |

| Services | Molding only | Tooling, molding, finishing, assembly under one roof |

| Global Reach | Limited regional service | Delivered 3,000+ molds to 38+ countries |

| Confidentiality | Basic NDAs | Strict IP protocols, secured data handling |

| Sustainability | Not always prioritized | Recyclable resins, eco-friendly processes, energy-efficient machines |

Compare Our Plastic Tooling Products

High-Precision Gear

Our high-precision gears are crafted using advanced injection moulding techniques, ensuring durability and accuracy for industrial applications.

- Material: Polycarbonate

- Tolerance: ±0.01mm

- Application: Electronics

- Feature: High Durability

VS

Custom Plastic Enclosure

Designed for electronic devices, our custom plastic enclosures offer robust protection and customizable features to meet specific needs.

- Material: PP

- Tolerance: ±0.02mm

- Application: Automotive

- Feature: Customizable Design

Overcoming Injection Molding Challenges

We know the complexities of molding — from tight deadlines to strict compliance. LXG addresses these with rapid prototyping, strict quality checks (FAI, CMM, SPC), ISO-certified processes, and cost-effective manufacturing, giving you confidence in every product.

Advanced Injection Molding Technology

Our facilities use cutting-edge machinery, precision tooling, and advanced software simulation to achieve world-class quality. We also specialize in multi-material molding, overmolding, and insert molding, enabling more complex designs and integrated solutions.

Our Testimonials

our client say's

Founded in 2000, Longxiang Group Limited (LXG Injection Molding) has grown into one of China’s most reputable mold makers, with 120 skilled employees and a 5,000 sq. meter workshop. Over the past 18+ years, the company has exported more than 3,000 molds to 38 countries worldwide. Its expertise spans automotive, electronics, IT, household products, and medical applications. With strict quality control, one-stop service, and rapid response support, LXG Injection Molding is a trusted global partner for precision plastic solutions.

Our Partners