Plastic Injection Molding Company in Pahang, Malaysia

LXG Injection Molding is a trusted Plastic Injection Molding Company in Pahang, Malaysia, delivering reliable plastic components for manufacturers across Malaysia and global markets. With 3000+ molds delivered worldwide, 200+ completed projects, operations in 38+ countries, and support from 1,200+ skilled professionals, we bring proven capability, stability, and confidence to every production program.

Instant pricing & DFM

Guidance from automotive molding experts

Tight tolerances, complex geometries, and multi-material capabilities

Proven expertise with 3,000+ molds delivered worldwide

Is Your Injection Molding Partner Holding You Back?

Too many companies face obstacles such as

Inconsistent part quality

failed assemblies, higher scrap rates, and costly recalls

Slow lead times

delayed product launches and missed market windows

Regulatory non-compliance

increased audit risks and lost certifications

Design limitations

constraints on innovation and product functionality

Manufacturing inefficiencies

inflated costs and reduced profitability

Injection MOLD Manufacturing on demand

100% Satisifeds Manufacturers

Get Instant Price, Projects lead time and DFM Feedback

Our mold injection manufacturer services

Injection Moulding

LXG Injection Molding delivers precision plastic parts using advanced machines and ISO processes, supporting prototypes to high-volume production with consistent quality, efficiency, and global manufacturing standards.

Plastic Tooling

Our tooling experts design durable, high-accuracy molds including single and multi-cavity systems, ensuring long tool life, reliable performance, and cost-effective manufacturing for every production requirement.

Rapid Prototyping

We provide fast, cost-effective prototyping using aluminum or soft-steel tooling, enabling quick design validation, functional testing, and faster transition from concept to full-scale production.

Global Reach, Local Support

LXG has delivered 3,000+ molds to over 38 countries worldwide.

Industries We Serve

Aerospace

Automotive

Consumer Electronics

Medical & Healthcare

Industrial & Robotics

Sustainable Packaging

Our Testimonials

our client say's

Founded in 2000, Longxiang Group Limited (LXG Injection Molding) has grown into one of China’s most reputable mold makers, with 120 skilled employees and a 5,000 sq. meter workshop. Over the past 18+ years, the company has exported more than 3,000 molds to 38 countries worldwide. Its expertise spans automotive, electronics, IT, household products, and medical applications. With strict quality control, one-stop service, and rapid response support, LXG Injection Molding is a trusted global partner for precision plastic solutions.

Get started with precision manufacturing

Complete Plastic Injection Molding Services in Pahang

LXG Injection Molding provides end-to-end plastic injection molding services in Pahang, supporting customers throughout the entire product lifecycle. From concept development to mass production, our services are designed to reduce risk, control costs, and maintain consistent quality.

As a dependable molding supplier in Pahang, our capabilities include mold design, tooling fabrication, sampling, validation, and long-term production management. We manufacture precise injection molding mold parts in Pahang for industries such as automotive, medical devices, electronics, industrial equipment, packaging, and consumer products.

Our engineering team works with a wide range of thermoplastics, including commodity, engineering, and high-performance materials. We handle both simple components and complex parts that require tight tolerances and stable repeatability. Location-based project management in Pahang ensures faster communication, easier design collaboration, and responsive technical support.

At the same time, our global manufacturing network enables efficient scaling when volumes increase or cost optimisation is required. This balanced approach makes LXG Injection Molding a strong partner for businesses seeking local reliability with international manufacturing strength.

Why Choose LXG Injection Molding in Pahang

Selecting the right injection molding company near me is essential for quality, cost efficiency, and on-time delivery. LXG Injection Molding is built to deliver predictable outcomes and long-term value.

3000+ molds delivered worldwide across diverse industries

200+ completed projects with proven manufacturing results

Active service coverage in 38+ countries

1,200+ professionals supporting engineering and production

Strict quality control at every manufacturing stage

Competitive pricing with transparent cost structures

Fast turnaround for rapid injection molding in Pahang

Scalable solutions from prototype to mass production

Local Pahang support with global manufacturing options

Dedicated project management and clear communication

Clients choose LXG Injection Molding because we prioritise consistency, accountability, and long-term partnerships.

Our Injection Molding Process in Pahang

Our mold injection manufacturing in Pahang follows a structured, easy-to-understand process designed to deliver consistent quality and efficient production.

The process begins with design review and engineering consultation. Our team evaluates part geometry, material selection, and manufacturability. This step is especially important for custom injection molding in Pahang, helping reduce tooling risks and improve part performance.

Next, we move into mold design and tooling development. Using advanced CAD software and precision machining, we create durable molds engineered for long tool life and repeatable accuracy. Each mold is inspected and tested before production.

Once tooling is complete, we conduct sampling and testing. Prototype plastic injection molding in Pahang allows clients to review fit, function, and appearance before approving full production. Any refinements are implemented quickly to meet specifications.

After approval, production begins. Our facilities support low-volume runs, pilot programs, and high-volume manufacturing. Quality checks are performed throughout production, followed by final inspection, packaging, and delivery. This disciplined approach makes LXG Injection Molding a dependable plastic injection molding service near me for businesses in Pahang.

Benefits of Plastic Injection Molding in Pahang, Malaysia

Plastic injection molding in Pahang offers strong advantages for companies serving Malaysian, ASEAN, and global markets. Local production improves collaboration, reduces lead times, and simplifies logistics.

Manufacturers benefit from faster prototyping and quicker production starts. Rapid injection molding prototyping in Pahang enables design teams to test and refine products without extended delays, supporting faster time to market.

Pahang’s access to Malaysia’s manufacturing ecosystem and transport networks supports efficient distribution. Local mold injection manufacturing in Pahang also helps ensure compliance with Malaysian and international quality standards, which is important for medical, automotive, and industrial applications.

By working with a local injection molding partner, clients gain better visibility and control over production. At the same time, LXG Injection Molding offers global manufacturing options for projects that require cost efficiency or higher volumes. This combination of speed, reliability, and flexibility delivers measurable value.

Methods & Technologies We Use

LXG Injection Molding uses proven manufacturing methods and modern technologies to support a wide range of production requirements. Our systems are designed to scale efficiently while maintaining consistent quality.

Custom Injection Molding in Pahang

We design and manufacture molds tailored to specific applications, ensuring durability, consistent performance, and repeatable quality.

Rapid Injection Molding Prototyping in Pahang

Our rapid injection molding prototyping in Pahang helps clients validate designs quickly, reduce development costs, and accelerate product launches.

High-Precision Tooling

Advanced tooling systems enable tight tolerances and reliable handling of complex geometries across production runs.

Low-Volume & Large-Scale Manufacturing

We support both short production runs and continuous high-volume manufacturing without compromising consistency.

All projects are supported by professional LXG Injection Molding services available at https://lxginjectionmolding.com/, ensuring expert handling at every stage of the manufacturing process.

Lowest Price Guaranteed Injection Molding in Pahang

LXG Injection Molding offers a lowest price guaranteed approach built on efficiency, transparency, and smart manufacturing strategies. Pricing is determined by part complexity, material selection, tooling requirements, and production volume.

We provide clear and detailed quotations so clients understand costs upfront. There are no hidden charges or unexpected fees. Our focus is on delivering long-term value rather than short-term pricing tactics.

For cost-sensitive projects, we compare local Pahang production with global manufacturing options. For time-critical or compliance-driven programs, local production offers faster turnaround and closer control. This flexible pricing model allows clients to choose the best solution without sacrificing quality.

Location-Specific Injection Molding Services Near You in Pahang

LXG Injection Molding proudly serves businesses throughout Pahang with responsive and reliable injection molding solutions. If you are searching for an injection molding company near me, our local support ensures faster communication and dependable delivery.

We work with manufacturers in automotive, medical, electronics, industrial, packaging, and consumer sectors. Local service allows quicker sampling, easier design revisions, and shorter lead times for injection molding mold parts in Pahang.

Our Pahang-focused service model, combined with global manufacturing strength, makes us a preferred molding supplier in Pahang for businesses of all sizes. From startups to established enterprises, we support projects with consistency, care, and technical expertise.

Frequently Asked Questions

What industries do you serve?

We serve automotive, medical, electronics, industrial, packaging, and consumer product industries.

Do you offer custom injection molding in Pahang?

Yes, we specialise in custom injection molding tailored to specific design and performance needs.

Can you handle prototype projects?

Yes, we provide prototype plastic injection molding in Pahang for fast design validation.

How fast is rapid injection molding?

Rapid injection molding prototyping in Pahang typically delivers parts within a few weeks.

Do you support low-volume production?

Yes, we support low-volume, pilot, and large-scale manufacturing programs.

What materials can you mold?

We work with a wide range of thermoplastics based on application requirements.

How do you ensure quality control?

We use inspections, testing, and process monitoring throughout the entire production process.

Do you offer global manufacturing options?

Yes, we provide global manufacturing solutions for cost efficiency.

How is pricing determined?

Pricing depends on tooling complexity, materials, production volume, and manufacturing location.

How do I get started?

Contact LXG Injection Molding to discuss your project requirements and receive a detailed quote.

Our Partners

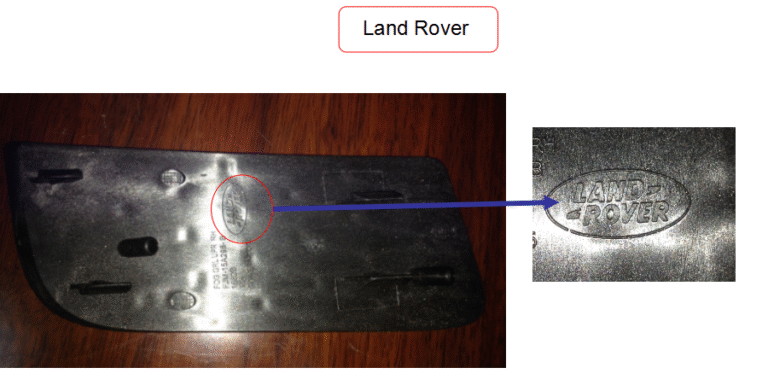

Our Work