At LXG Injection Molding, we specialize in automotive injection molding solutions that power the future of mobility. From rapid prototyping to high-volume production, our precision-engineered plastic components support traditional, electric, and autonomous vehicles. Whether you need dashboards, trims, connectors, housings, or lightweight structural parts, LXG delivers speed, reliability, and accuracy that automotive manufacturers trust.

Instant pricing & DFM

Guidance from automotive molding experts

Tight tolerances, complex geometries, and multi-material capabilities

Proven expertise with 3,000+ molds delivered worldwide

Why Automotive Injection Molding?

Modern vehicles demand lightweight, durable, and high-performance plastic components to improve safety, fuel efficiency, and overall performance. Plastic injection molding in automotive applications offers:

Lightweight alternatives to metal parts → improving efficiency & reducing costs

Design flexibility → complex shapes and detailed geometries made easy

High-volume scalability → from prototype to millions of units

Consistent quality & durability → crucial for safety-critical automotive systems

Material versatility → from standard resins to advanced, high-temperature engineering plastics

At LXG, we combine these advantages with unmatched speed and global delivery to help automotive OEMs and Tier 1 suppliers bring innovations to market faster.

The Way We Work

Understanding Client Requirements

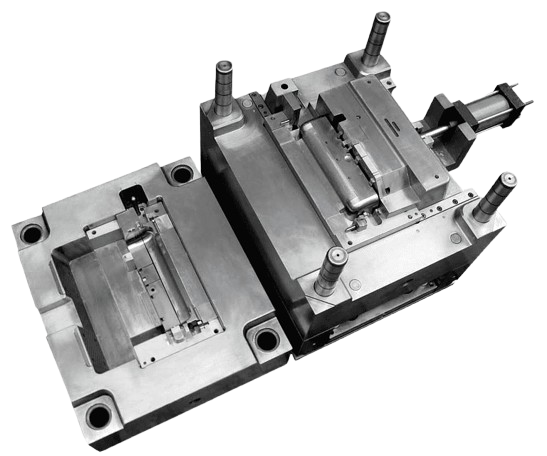

Precision Mold Development

Quality Control & Testing

Design & Material Selection

High-Quality Injection Molding

On-Time Delivery & Support

Our Work

Our Expertise & Capabilities

Prototype Automotive Injection Molding – Fast turnaround for design validation and testing.

Custom Plastic Molds for Vehicles – Optimized for dashboards, trims, connectors, housings, and more.

Multi-Material & Overmolding – Enhanced functionality with integrated seals, gaskets, and aesthetic finishes.

High-Performance Resins – Including glass-filled nylon, ABS, PEEK, and flame-retardant materials.

End-to-End Solutions – Tooling, molding, finishing, assembly, and packaging — all under one roof.

Commitment to Quality

At LXG Injection Molding, quality is non-negotiable. For automotive projects, we:

Follow APQP & PPAP standards for automotive quality control

Provide full documentation and traceability for compliance

Use CMM inspection, SPC monitoring, and rigorous durability testing

Ensure all automotive parts meet global safety and performance regulations

Industries We Serve

Aerospace

High-quality plastic components engineered for demanding aerospace applications — from early prototyping and wind tunnel testing to hot-fire trials and final launch readiness. Our lightweight, durable parts help improve performance....

- Read More

Automotive

Supporting the evolution of mobility with rapid prototyping, bridge tooling, and full-scale production for traditional, electric, and autonomous vehicles. From dashboards and trim to connectors and housings, we deliver precision components with....

- Read More

Consumer Electronics

Delivering functional prototypes and on-demand production of casings, connectors, and housings for consumer and computer electronics. Our advanced overmolding and multi-material capabilities enhance both aesthetics and functionality.....

- Read More

Medical & Healthcare

Accelerating the development of life-saving medical devices and healthcare products. With ISO 13485 compliance, FDA-approved resins, and clean room assembly, we ensure biocompatibility, safety, and reliability for medical applications.....

- Read More

Industrial & Robotics

Durable, high-performance parts for robotics, automation systems, and industrial equipment. Our engineering resins and fiber-reinforced polymers withstand extreme loads, ensuring strength and long service life in demanding environments.....

- Read More

Sustainable Packaging

Partnering with innovators in eco-friendly packaging to create biodegradable containers, recyclable components, and lightweight designs. Our sustainable molding practices align with global initiatives to reduce waste and carbon.....

- Read More

Get Instant Price, Projects lead time and DFM Feedback

Our Partners